Construction sites expose workers to more hazards than almost any other industry, with a non-fatal injury rate of 2,500 per 100,000 workers reported for 2024/25 alone.

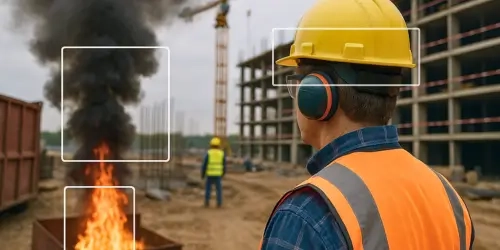

Workers face daily dangers like falling objects, hazardous materials, heavy machinery, fire risks, dust and excessive noise. One lapse in Personal Protective Equipment (PPE) or an undetected smoke trail can lead to safety incidents that can cost you millions.

To ensure workplace safety in this high-risk environment, contractors must comply with strict safety management regulations set by the Health and Safety Executive (HSE). Yet, traditional methods (like manual spot checks) create more compliance chaos than control.

So, how do you ensure compliance and safety protocols are followed when teams are scattered across multiple sites and compliance violations can happen in seconds? AI-video analytics for PPE, fire and smoke detection provide a triple solution: a single integrated system that tracks workers, scans building sites for non-compliance issues and detects fire risks in real-time.

If you're an IT manager overseeing construction site systems, understanding the correlation between smart detection and HSE compliance is more important than ever before, and this article covers everything about it.

4 Problems With Traditional Monitoring Methods

Traditional PPE compliance and fire safety in construction relied heavily on sporadic inspections and paper-based documentation. Nowadays, these methods can no longer keep pace with modern construction sites where teams work across multiple locations and incidents require immediate action.

Here are just 4 issues traditional monitoring methods cause:

-

Vendor sprawl drains budgets: Construction managers often use 5+ monitoring platforms for security, PPE detection, fire safety and environmental monitoring. Each system has its own login and set of siloed reports, with no easy way to sync data across platforms. For IT leads, this fragmentation means managing multiple contracts and cybersecurity requirements, quickly turning operations into escalating costs.

-

No real-time visibility: Manual PPE checks occur periodically; often once or twice a week. Fire detection relies on basic fire alarm systems that only alert security personnel when conditions have deteriorated. By the time violations are identified, damage is often already done.

-

Cybersecurity exposure: Every additional monitoring system creates another vulnerability. Separate vendor platforms/tools mean different security protocols and data handling practices. For construction IT managers, these online safety risks are a real concern that keeps growing with each new system added.

-

Compliance pressures: With tightened compliance, regulators demand real-time data for compliance and ESG reporting. Handwritten monitoring logs stored in archive files are difficult to retrieve when HSE inspectors arrive, exposing construction firms to costly compliance gaps and fines.

Read more:

-

Why Construction Site Cybersecurity and Safety Monitoring Go Hand in Hand

-

Managing Vendor Sprawl on your Construction Site: Why Consolidated Monitoring Matters

PPE and Fire Regulations Every UK Contractor Should Know

The UK's construction sector operates within comprehensive health and safety frameworks designed to protect workers and communities. Non-compliance poses risk to worker safety and can result in substantial fines, project delays and reputational damage when things go wrong.

| Regulation | Purpose | Compliance requirements |

| Health and Safety at Work Act (HASAWA) 1974 | UK employers must do what's "reasonably practicable" to protect workers. |

|

| Working at Height Regulations 2005 | Prevents fall from height risks. |

|

| Control of Substances Hazardous to Health Regulations (COSHH) | Protects workers from harmful dust, gases, chemicals and fumes. |

|

| Personal Protective Equipment at Work Regulations (PPER) 1992 | Requires employers to provide suitable PPE for various construction tasks. |

|

| The Regulatory Reform (Fire Safety) Order (FSO) 2005 | A "responsible person" must assess and manage fire risks. |

|

| Construction (Design and Management) CDM 2015 | Main regulation governing site safety during design, planning and construction. |

|

It's worth mentioning that construction teams must keep detailed records showing compliance. You can incur hefty fines if you fail to maintain documentation, even if no safety breach occurs

.

Cost of non-compliance

In 2024, the total cost of work-related injuries in the UK exceeded £1 billion. Many such incidents could've been easily prevented with the correct use of PPE. The HSE also estimates around 4,000 annual COPD-related deaths (chronic obstructive pulmonary disease), largely linked to work-related exposure to hazardous substances.

These figures highlight just how serious the health risks of non-compliance can be.

Beyond injuries and fatalities, failing to meet safety compliance regulations can seriously put your reputation and bottom line at risk:

-

£160,000 penalty for ignoring fire safety standards

-

£60,000 fine for failing to protect workers against hazardous dust

-

£40,000 in damages for falls from height due to inadequate PPE

-

Jail time for gross negligence

Read more:

-

The Importance of IT and HSE Collaboration in Construction

-

Rethinking Construction Compliance Through Smart Monitoring Systems

How PPE, Fire and Smoke Analytics Work to Ensure Construction Site Safety

Our AI-powered, IoT-based smart detection systems for PPE, fire and smoke easily integrate with our CCTV Towers and Temporary CCTV solutions. Using advanced software to continuously monitor PPE usage, systems detect the earliest signs of smoke or flames and even keep a lookout for intruders/trespassers.

PPE Monitoring and Detection Systems

PPE violations remain one of the leading causes of construction injuries and HSE enforcement action. Workers entering restricted areas without the correct gear create immediate safety and compliance risks.

How do they work?

Scanning construction sites with advanced AI-video analytics constantly, PPE detection technology identifies whether workers are wearing the right PPE. The system detects:

-

Hard hats and safety helmets

-

High-visibility vests

-

Safety harnesses

-

Eye, hearing and respiratory protection

-

Safety footwear and gloves

Standing up to 6 metres tall with a near-360° field of view, CCTV Towers equipped with PTZ (Pan-Tilt-Zoom) cameras and advanced PPE video analytics monitor sites in real-time. They're so sophisticated that they can distinguish between genuine safety risks and false alarms caused by passing wildlife or weather conditions.

Through remote monitoring, mobile keyholding and instant alerts, project managers are immediately notified when the system detects unsafe behaviour. This proactive approach enables quick corrective actions, preventing injuries proactively.

All PPE detection footage feeds into Stellifii, our cloud-based compliance platform. IT leads and site managers can access all monitoring information through a single dashboard and generate audit-ready documentation 5X faster than legacy systems, from any device.

Read more: PPE Detection in Action: Keeping Construction Projects Compliant with HSE

Smoke and Fire Detection Systems

Construction sites are full of fire hazards: hot works, flammable liquids, electrical installations and combustible waste. With so many dangers in play, it's little surprise that nearly 2,000 building site fires occurred in England between 2014 and 2019.

The problem with traditional smoke and fire alarms is that they often react too late, only sounding when smoke has already built up. By this point, a small incident can quickly escalate into a blaze that's far harder to contain.

How do they work?

Identifying visible smoke and flame patterns directly through advanced night-vision cameras, site teams gain a vital time advantage when it matters most. Systems detect fire hazards through high-tech visual analysis, such as:

-

Thin smoke trails from smouldering materials

-

Heat/colour signatures indicating fire risks

-

Flickering light pattern characteristic of open flames

-

Rapid temperature changes

This early warning functionality detects fires in seconds, long before basic smoke detectors even react. As with our PPE detection systems, site managers receive instant alerts when fire hazards are detected, enabling immediate investigation before minor issues turn bad.

Our fully-managed fire systems comply with the Regulatory Reform (Fire Safety) Order, which requires duty holders to assess and manage potential fire risks throughout all construction phases. Automated reports are easily retrievable through our AES256-encrypted Stellifii platform for compliance and insurance purposes.

Unlike manual inspections, AI-driven detection delivers real-time monitoring, spotting risks as they emerge. When connected to NSI Gold Accredited monitoring centres, incidents trigger immediate action, reducing the risk of escalation.

Read more: The Modern HSE Playbook for UK Safety Leaders

Supporting technologies

Smart detection systems for PPE and fire go hand-in-hand with other smart integrations:

-

Automatic Number Plate Recognition (ANPR) logs vehicle movements entering/exiting sites.

-

Environmental Monitoring Solutions track air quality, noise, vibrations and weather in real-time.

-

Redeployable CCTV Cameras provide flexible coverage in hard-to-reach areas.

-

Time Lapse Video documents project progress for stakeholder updates.

6 Benefits of Smarter PPE, Fire and Smoke Detection in Construction

Let's quickly go over the 6 advantages of how AI-video analytics for PPE, fire and smoke benefits construction firms in the UK:

-

Enhanced worker safety: AI detection identifies missing PPE and fire hazards in real-time, enabling immediate action when it matters most.

-

Reduced vendor sprawl: Consolidating PPE, fire detection, asset protection and environmental monitoring eliminates multiple system management. One platform delivers multiple capabilities, reducing complexity for IT teams.

-

Real-time visibility: Cloud-based dashboards provide instant oversight across all building sites while systems generate timestamped records of monitoring activity and corrective action.

-

Automated compliance: Stellifii automates compliance documentation for PPE, fire and smoke at the click of a button, freeing site teams from time-draining manual tasks.

-

Proactive cost control: Early detection prevents injuries, project delays and HSE penalties. Smart monitoring and proactive risk management can also reduce costs by up to 88% compared to manned guards and potentially qualify for lower insurance premiums.

-

Strategic IT leadership: Deploying intelligent AI-powered video analytics demonstrates IT's value to stakeholders through clear ROI: fewer incidents, less cybersecurity risk and all-in-one vendor consolidation.

Read more:

Improve Construction Site Safety With AI-Video Analytics

In the UK, IT and construction managers can maintain site safety and compliance with AI-video analytics for PPE, fire and smoke detection.

Using advanced video analytics and machine learning, these systems offer real-time visibility when it matters most, help keep workers safe and ensure regulatory compliance with minimal effort for you and your team.

With 6 regional hubs and over 20-years of site monitoring expertise, our fully-managed smart detection systems have set a new standard in UK construction.