According to recent Health and Safety Executive (HSE) reports, more than 500 construction workers are estimated to die annually from lung diseases caused by silica dust exposure. To prevent workplace hazards and remain compliant with HSE, construction firms must ensure workers wear personal protective equipment (PPE) during all site activities and train teams on site-specific safety protocols.

This works well in theory, but when site managers are managing multiple sites while trying to keep projects on schedule, monitoring PPE efficiently becomes nearly impossible.

On top of that, outdated methods, like manual inspections and logging events via legacy systems (spreadsheets, email threads, etc.), can't keep pace anymore, leading to compliance gaps that could shut down projects when HSE inspectors arrive unannounced and workers lack proper PPE.

In this article, we outline a simpler way to stay compliant: automated PPE detection that prevents costly project delays and HSE fines before they happen. We'll also explain PPE detection in action, the risks of non-compliance and how WCCTV's smart detection systems help teams maintain safety standards without slowing down operations.

How PPE Detection Actually Works in Construction

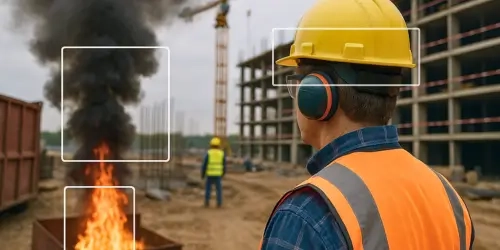

Automated PPE detection and monitoring help you identify when workers enter high-risk areas without the appropriate PPE (including improperly worn PPE), preventing HSE infringements before they escalate into enforcement action or project delays.

Rather than relying on physical spot checks and manual supervision that may miss violations, smart detection systems monitor sites continuously, automatically detecting non-compliance in real-time.

Here's how PPE detection works in practice:

Detection process

-

CCTV Tower integration: PPE detection systems are optional add-ons to our Rapid Deployment CCTV Towers and Temporary CCTV systems. The detection software runs through existing CCTV cameras already monitoring your site for security reasons. Towers, standing up to 6 metres tall, with near-360° visibility, ensure 24/7 PPE monitoring across all work zones.

-

Advanced camera technology: PTZ (Pan-Tilt-Zoom) night vision cameras with up to 40X zoom constantly scan building sites day and night. Using thermal imaging and advanced technology, they can spot missing or wrongly worn PPE with near pinpoint accuracy, even in low light conditions or adverse weather.

-

AI-video analytics: Using machine learning and advanced algorithms, AI-powered PPE detection "teaches" CCTV cameras what proper PPE usage is and what's not. When the system detects workers missing protective gear (hard hats, safety glasses, hearing protection, etc.), it quickly notifies safety teams so corrective action can be taken while automatically timestamping every event for compliance audits.

Read more:

Alerts and logging

-

Professional remote monitoring: AI PPE detection means alerts are sent directly to NSI Gold monitoring centres when violations occur. Here, trained personnel assess the situation in real-time and instantly notify site managers, while issuing quick actions such as live audio voice-down challenges to ensure worker safety. Each incident is logged and timestamped with the corresponding video footage, so there's a clear paper trail for internal audits and HSE inspections.

-

Timestamped records: Smart monitoring provides safety managers with 24/7 "eyes in the sky" for all health and safety purposes onsite. Detection models generate precise time-stamped records, capturing date/time, location, type of missing PPE, violation duration and corrective action taken. These records are stored automatically in cloud-based platforms, proving due diligence and preventing project delays when HSE inspectors drop in.

Read more: How Cloud-Based Tools Are Changing Construction Admin

Automated compliance data

HSE inspectors can request compliance reports and monitoring logs at any time. When site information is stored across multiple vendors or manual processes, this task becomes 10 times harder.

All construction site data, including PPE compliance, feeds directly into Stellifii, our cloud-based monitoring platform. By creating a unified dashboard with everything in one place, this smarter approach to surveillance, monitoring, historical trends and HSE reporting sets a new standard for UK contractors.

For instance, did you know that under the Control of Substances Hazardous to Health Regulations (COSHH), employers must keep detailed health records for the duration of employment plus 40 years for certain exposures such as silica dust? AI-powered PPE systems automate this record-keeping for you, offering searchable timeframes and data exports 5X faster than legacy systems.

Read more:

Supports other site monitoring integration

PPE detection systems work alongside other smart site monitoring integrations, giving project managers complete oversight across every inch of working zones:

-

Smoke and fire detection identify early fire hazards and fumes that could endanger workers.

-

Intrusion detection monitors building sites for signs of theft and unauthorised access.

-

Environmental monitoring tracks air quality, noise and weather that may affect PPE requirements.

Read more:

-

Noise Monitoring Compliance: Futureproofing UK Construction Sites

-

Weather Monitoring Tools That Keep Construction Projects on Track

HSE Regulations for PPE Monitoring Explained

UK construction projects must comply with numerous regulations for personal protective equipment. Understanding these requirements helps site managers recognise why automated detection is important for maintaining regulatory compliance.

Here's what HSE expects:

-

Risk assessments: "Principal contractors" must conduct and document thorough risk assessments, pinpointing hazards requiring PPE and specifying the equipment needed in each working zone (e.g., safety glasses during welding work).

-

Training and enforcement: Employers must provide workers with the appropriate PPE to prevent workplace injuries free of charge. They must also enforce PPE through continuous monitoring and corrective action.

-

Accountability: Project managers must demonstrate "reasonable practicable" steps to enforce PPE usage. Manual spot checks done once per shift won't meet HSE requirements.

-

Compliance: Evidence of ongoing PPE monitoring, not reactive documentation after incidents have occurred.

Regulations governing PPE usage in the UK

| HSE regulations | Description | Safety compliance requirements |

| Personal Protective Equipment at Work Regulations (PPER) 1992 |

|

|

| Health and Safety at Work Act (HASAWA) 1974 |

|

|

| Construction (Design and Management) CDM Regulations 2015 |

|

|

Without continuous PPE detection monitoring, construction firms expose themselves to stop notices and costly PPE non-compliance liabilities when inspectors arrive with no prior warning.

The cost of non-compliance

Construction-related injuries accounted for nearly 14% of the UK's total work-related injuries, costing £800 million in 2023. And the HSE estimates that around 4,000 Chronic Obstructive Pulmonary Disease (COPD) deaths every year could be linked to work exposures like silica dust.

On top of this, several major organisations faced substantial penalties for health and safety violations in the UK earlier this year (2025):

-

Cambridgeshire County Council: £6 million + £292,000 costs

-

British Airways PLC: £3.2 million + £20,900 costs

-

Industrial Chemicals Ltd: £2.5 million

-

TATA Steel: £1.5m + £26,000 costs

-

Bestway Northern Limited: £1m + £11,900 costs

PPE non-compliance hits your bottom line financially while also delaying project timelines and putting your reputation at serious risk.

How Smart PPE Detection and Monitoring Benefits UK Construction

Here are just 5 ways in which smart PPE detection benefits the construction sector:

-

Keeps projects on track: Automated PPE detection prevents HSE bottlenecks with PPE issues that could derail project schedules. This keeps projects moving safely and compliantly while boosting productivity.

-

Ensures compliance: When HSE inspectors arrive without warning, sites with smart PPE monitoring show proactive project management, satisfying HSE inspections with minimal effort.

-

Ensures workplace safety: Workers entering high-risk zones without hard hats, reflective vests or hearing protection trigger instant alerts, allowing for quick corrective action that leads to fewer workplace injuries.

-

Fewer manual checks: Manual supervision requires managers to be physically onsite. AI PPE detection with 24/7 remote monitoring does not, saving you hours each week in the long run.

-

Reduces admin tasks: Meeting HSE, PPER, CDM, HASAWA and COSHH regulations demands substantial administrative effort when done manually. Automating PPE data alongside other site monitoring obligations reduces rework and delays by half the time.

Detect PPE Usage the Smart Way

Since HSE inspectors can arrive at any given time, PPE compliance failures can cost you money and lead to significant project delays. The best way to combat this is with continuous PPE detection and monitoring throughout every project phase, not occasional spot checks scattered here and there.

With 6 regional hubs and over 20-years of monitoring expertise, we understand just how important real-time PPE detection is for the construction industry. That's why we offer fully-managed smart detection solutions to construction companies of any size.

Keep construction projects HSE-compliant and free from avoidable delays with WCCTV. Contact our monitoring experts to discuss how our smart detection systems and Stellifii platform can help you stay fully aligned with health and safety regulations without slowing down operations.